A tripper conveyor is a form of conveyor belt used in construction mining and other large-scale earth-moving businesses. The surcharge angle on the average will be 5 degrees to 15 degrees less than the angle of repose.

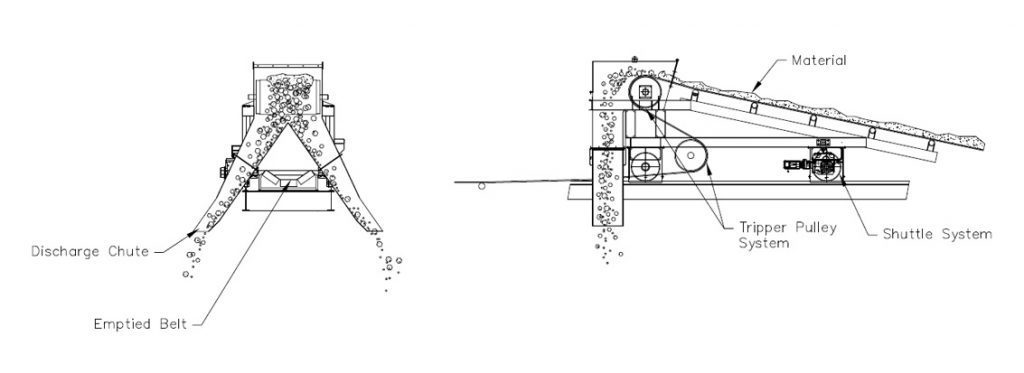

Outlets can be placed above one or both ends or a tripper carriage which can discharge the material in the full length of the belt.

. The FEECO design incorporates a raising bed plate that allows the use of a plow even on troughed belts. FEECO belt plows are designed to increase a belt conveyors material discharge control capabilities. A Tripper Conveyor is a form of conveyor belt used in construction mining and other large-scale earth-moving businesses.

Choose the idler shape. A simple tripper car. Therefore belt conveyor design capacity will be.

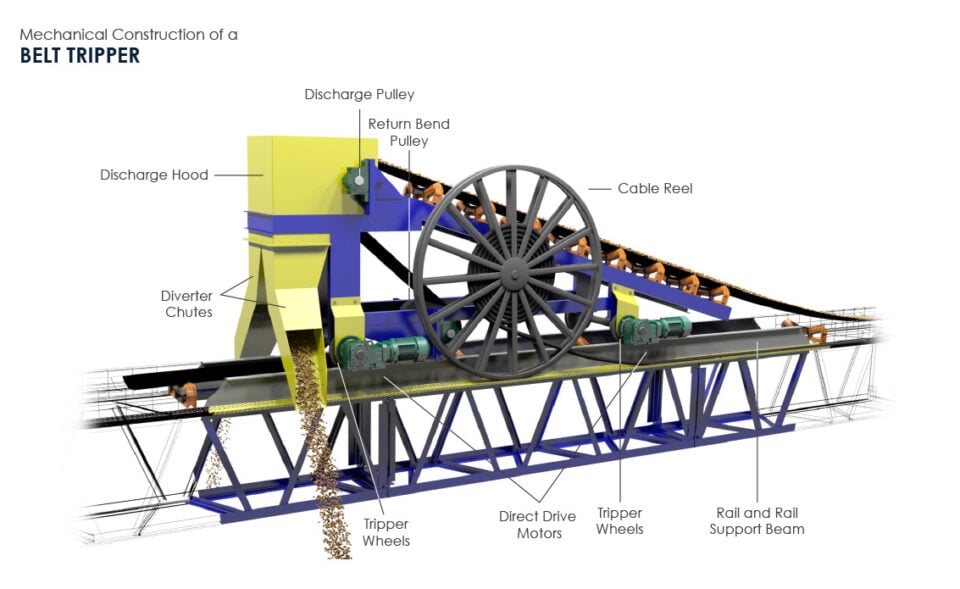

BELT TRIPPERS FEECO belt trippers are custom designed and built to accommodate your desired specifications with the same guidelines you can expect from all of our equipment ie precision engineering quality components and heavy-duty construction. Depending on the height of the pillars tripper conveyors are capable of large quantity stockpiles. This particular type of conveyor was designed to ferry debris earth rocks etc.

The car moves back and forth to allow mined material to be discharged into different chutes - feeding multiple conveyor. Travelling - Bogie move the machine on rail track along the stockstorage yard. The belt conveyor consists of.

T e is the final summarization of the. Select the belt width and speed based on a capacity design factor of 80 the theoretical maximum tons per hour reduction of capacity. Find out the design capacity for down line belt conveying system.

Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low. The tripper car moves in both directions to make a long pile on one or both sides of the belt conveyor. This allows for surge loading and reduces spillage due to.

Much like belt trippers belt plows can release material on either side of the belt at pre-designated locations. Project Name Tripper Example Company AC-Tek Conveyor Name Tripper 1 Filename Tripper Conveyor Location Date February 16 2016 Description Tripper Conveyor Example Sidewinder v606 - Conveyor Design Software Advanced Conveyor Technologies Inc. The belt conveyor can be fitted stationary or mounted on rails.

Belt width to which trippers are fitted such as 650 800100012001400 and 1600. A tripper car is a mobile belt conveyor that rides on rails. Conveyor Name Tripper 1 Filename Tripper Conveyor Location Date February 16 2016 Description Tripper Conveyor Example Sidewinder v606 - Conveyor Design Software Advanced Conveyor Technologies Inc.

This particular type of conveyor was designed to ferry debris earth rocks etc uphill. 27 - 12 15 2. Abstract Industries and factories utilise conveyor systems for transport of goods bulk materials and manufactured parts from place to place in order to save money time and manpower.

The travel of the tripper car is PLC controlled and programmed to build either a Cone Shell or a Chevron stockpile. Feed to the conveyor the cross-sectional area of the load on the conveyor belt is the determinant of the belt conveyor capacity. 13 Travelling tripper on conveyor Nos.

The tripper conveyor consists of a horizontal Belt Conveyor supported over the. Determine the surcharge angle of the material. The loaded conveyor at the design velocity of the belt V in fpm.

Page 4 33 Conveyor Profile Overall length 2116 ft -Overall height 178 ft - True Length 21682 ft. TRIPPER CONVEYOR DESIGN PDF December 1 2018 The Tripper Conveyor is designed to load individual bins by moving over the top of bins on the Layco Stationary Conveyor. Page 4 5 Conveyor Profile Overall length 2116 ft -Overall height 178 ft - True Length 21682 ft.

1 To determine the effective tension T e it is necessary to identify and evaluate each of the individual forces acting on the conveyor belt and contributing to the tension required to drive the belt at the driving pulley. 121 Trippers for belt width more than 1 600 mm are not included in this standard. They are also known as tiered or stepped conveyers and the term tripper is a colloquialism that formed after they came into widespread use.

Belt Conveyor Capacity Table 1. The purpose of the belt tripper or traveling tripper is to add versatility and functional-. This manual is short with quick and easy reading paragraphs very practical for calculations of belt chain conveyors and mechanical miscellaneous in the metric and imperial system.

The tripper car is installed in a structure suspended from the building roof. We can use it to handle sand gravel aggregate iron. SKE provide traveling tripper conveyor design service.

Such trippers may 32 Tripper shall be of following four types. Select a suitable conveyor belt. Internal tripper cars feed multiple mills for the processing of the ore multiple silos for storage or multiple tranfer conveyors.

Design Aspects of a Motorised Travelling Tripper Saurabh Rane Subhashis Dey. Conveyors having belts of widths up to 1600 mm. 2266 Design of Drive 63 227 Minimum Pulley Diameters for Belts 63 228 Bend Snub Takeup and Tail Pulleys 63 229 Enclosures for Belt Conveyors 64 230 Idler Selection 64 231 Conveyor Belt Troubles 66 232 Selected Nomenclature for Section 2 66 233 Specification for Inclined 30 Belt Conveyor 72.

Drive station Tightening section Conveyor belt Extensions from 05 m to 20 m Tripper carriage. Following are the three basic movements in a stacker. Determine the density of the material in pounds per cubic foot lbft3.

Belt Conveyors are also a great option to move products through elevations.

Tripper Car 3d Cad Model Library Grabcad

Design Aspects Of Multiple Driven Belt Conveyors Semantic Scholar

Tripper Car 3d Cad Model Library Grabcad

Ab 10 03 Internal Tripper Car Pdf Belt Mechanical Mining

0 comments

Post a Comment